Oxygen and Nitrogen generator plant

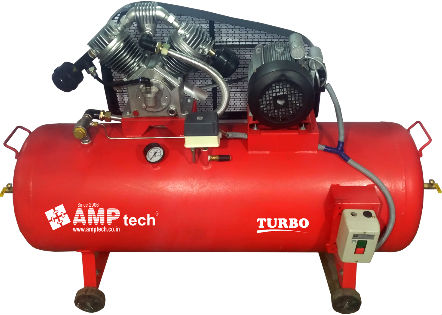

FEED AIR COMPRESSOR

| Type Of Compressor | Lubricated Screw Compressor |

| Duty | Continuous |

| Make | As per Client Need |

| Quantity | 1 No. |

| Delivered flow of Each Compressor | 60 Nm3/Hr Nm3/hr |

| Power Consumption | 7.5 kw |

| Discharge Pressure | 7 Bar G |

| Cooling | Air Cooled |

| Area Classification | Safe – Non Hazardous |

Technical Specification

| Model | CIG 1099N2. |

| Mounting | Skid Mounted – Pre Commissioned. |

| Capacity of Plant | 10 Nm3/Hr |

| Oxygen in outlet gas | 1% (10000 PPM). |

| No Of Modules | ONE. |

| Operation | Automatic With PLC – Non Stop 24 Hrs. |

| Turn Down Ratio | zero to 100% |

| Operating temperature | 40 Deg C Max |

| CMS QUANTITY | 60 Kgs |

| Compressed Air requirement | 60 Nm3/Hr @ 7 BarG. |

| Power consumption | 7.5 kw. |

| Discharge pressure Ex PSA | 5.5 Bar g. |

| Atmospheric Dew Point | Minus 40 degree C. |

| Surge Tank Volume | 500 ltrs. |

| Storage Tank Volume | 5 M3. |

| Oxygen Gas Analyzer( Online ) | Provided with Two Alarms. |

| Oxygen Level - Purity Check | Continuous – Online. |

| Size of the skid in Meters | 3 X 2.5 X 3 [L x W x Ht]. |

| Design Code | As per ASME Sec VIII DIV -1. |

| Area Classification | Non Hazardous – Safe Area. |

| Air Receiver | 700 ltrs. |

| Cooling Water Required | 1.0 M3. |

NITROGEN STORAGE TANK

| Capacity of Nitrogen receiver | 5 M3 |

| Storage Pressure | 5.5 BarG |

| Working Pressure | 5.5 BarG Max |

| Design Pressure | 10.5 BarG |

| Test Pressure | 10 BarG |

| Design Code | ASME Sec VIII DIV I |

| Design Temperature | 75 DegC |

| Accessories | Air Coolesafety Valve / Drain valve/ nozzles/ manhole |

AIR RECEIVER

| Capacity of Air RECEIVER – Dry AIR | 750 Ltr |

| QTY | ONE No. |

| MOC | SA 516 Gr 70 |